Turtle Clan Global

Owns, Manufactures, and Sells TurtleCRETE®

TurtleCRETE® is a line of eco-friendly, extreme temperature resistant, anti-corrosive coating formulas mandated and specified for use by the

United States Navy, Department of Transportation, and the Department of Interior as a superior protective coating and repair product.

Multi- purpose TurtleCRETE is an advanced, inorganic, cementitious, phosphate bonded ceramic

that is simply mixed with water, can be 'built up' in layers, and can either be

troweled, poured, sprayed, foamed, or pre cast for endless applications.

Next generation TurtleCRETE self-bonds to carbon steel, concrete, glass, and wood, and is impervious to harsh environmental conditions such as

extreme temperatures or corrosion.

TurtleCRETE is a safe, superior, permanent alternative to Portland cement and epoxy repair products, and safe for over water applications, safe for workers, and safe for the environment.

TurtleCRETE is a next generation solution with extensive applications in several industries.

Science & Technology

TurtleCRETE... A Fundamentally Different Approach

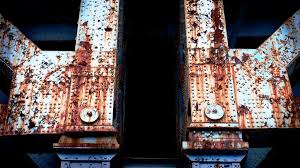

Traditional industrial coatings only delay the onset of corrosion, while TurtleCRETE permanently prevents corrosion by 'chemically bonding' to substrates, actually fusing to the substrate like a 'shield of armor', unlike polymer coatings, that just sit on top of the substrate, allowing moisture to penetrate, which is what causes corrosion to occur.

DoE: Hazardous and Nuclear Waste Encapsulation...

Phosphate Bonded Ceramic

TurtleCRETE is am extremely user-friendly and highly effective approach to

protecting mission critical substrates from extreme temperatures and corrosion,

and is easy to apply using standard industrial pump systems.

Two components, water and the TurtleCRETE powder, are combined in either dry or wet application systems before contact with substrate.

Because TurtleCRETE is a phosphate bonded ceramic and has superior insulative and compression strength capabilities,

it prevents extreme temperatures and corrosive materials from ever reaching the substrate...

making it ideal for micro and macro encapsulation of hazardous and nuclear waste streams.

Owns, Manufactures, and Sells TurtleCRETE®

TurtleCRETE® is a line of eco-friendly, extreme temperature resistant, anti-corrosive coating formulas mandated and specified for use by the

United States Navy, Department of Transportation, and the Department of Interior as a superior protective coating and repair product.

Multi- purpose TurtleCRETE is an advanced, inorganic, cementitious, phosphate bonded ceramic

that is simply mixed with water, can be 'built up' in layers, and can either be

troweled, poured, sprayed, foamed, or pre cast for endless applications.

Next generation TurtleCRETE self-bonds to carbon steel, concrete, glass, and wood, and is impervious to harsh environmental conditions such as

extreme temperatures or corrosion.

TurtleCRETE is a safe, superior, permanent alternative to Portland cement and epoxy repair products, and safe for over water applications, safe for workers, and safe for the environment.

TurtleCRETE is a next generation solution with extensive applications in several industries.

Science & Technology

TurtleCRETE... A Fundamentally Different Approach

Traditional industrial coatings only delay the onset of corrosion, while TurtleCRETE permanently prevents corrosion by 'chemically bonding' to substrates, actually fusing to the substrate like a 'shield of armor', unlike polymer coatings, that just sit on top of the substrate, allowing moisture to penetrate, which is what causes corrosion to occur.

DoE: Hazardous and Nuclear Waste Encapsulation...

Phosphate Bonded Ceramic

TurtleCRETE is am extremely user-friendly and highly effective approach to

protecting mission critical substrates from extreme temperatures and corrosion,

and is easy to apply using standard industrial pump systems.

Two components, water and the TurtleCRETE powder, are combined in either dry or wet application systems before contact with substrate.

Because TurtleCRETE is a phosphate bonded ceramic and has superior insulative and compression strength capabilities,

it prevents extreme temperatures and corrosive materials from ever reaching the substrate...

making it ideal for micro and macro encapsulation of hazardous and nuclear waste streams.

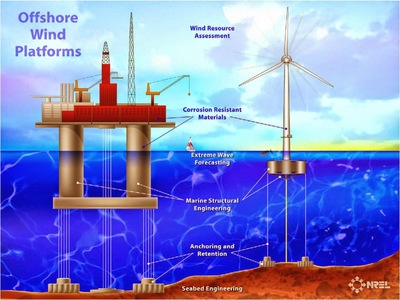

oil and gas Industry

Extreme Temperature & Corrosion Protection Solutons For The Energy Industry & Beyond...

TurtleCRETE prevents corrosion where it matters most... Refineries, natural gas pipelines, marine terminals, and more.

When it comes to protecting mission critical steel, concrete, and wood assets,

TurtleCRETE is the preferred protective coating provider to the military, energy, transportation, infrastructure, shipyard industries...

TurtleCRETE prevents corrosion where it matters most... Refineries, natural gas pipelines, marine terminals, and more.

When it comes to protecting mission critical steel, concrete, and wood assets,

TurtleCRETE is the preferred protective coating provider to the military, energy, transportation, infrastructure, shipyard industries...

Fire Resistant

Flame Spread Rating of Zero

TurtleCRETE is a Class "A" Fire Rated Material with a ZERO flame spread rating.

Because TurtleCRETE is completely inorganic, it will not burn, even when exposed directly to flame.

TurtleCRETE will never burn... It's like a rock.

Most corrosion resistant coatings, many of which are organic, offer no such level of temperature resistance or flame spread protection.

Fire Resistant

Flame Spread Rating of Zero

TurtleCRETE is a Class "A" Fire Rated Material with a ZERO flame spread rating.

Because TurtleCRETE is completely inorganic, it will not burn, even when exposed directly to flame.

TurtleCRETE will never burn... It's like a rock.

Most corrosion resistant coatings, many of which are organic, offer no such level of temperature resistance or flame spread protection.

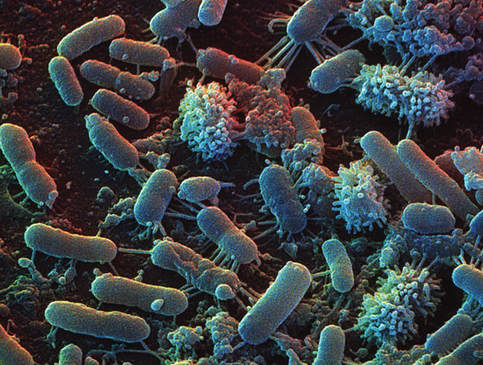

Antimicrobial Protection

TurtleCRETE delivers antimicrobial protection unmatched by any other corrosion resistant coatings.

When a microbe comes in contract with the TurtleCRETE protective coating, the moisture in the organism causes a tiny amount of phosphate to leach from the surface of the ceramic. The pH in the phosphate creates an environment where harmful microbes such as bacteria, fungus, protozoa, or virus, simply cannot survive.

For substrates that must be protected from corrosion that are also in close proximity to humans or animals, such as offshore oil platforms, ships crew quarters, railroad car compartments, livestock feed areas, hospitals, laboratories, hotels, etc...TurtleCRETE offers a safe and superior solution by preventing and eliminating both rust and unwanted bacteria, viruses, fungus, and other microbes.

TurtleCRETE delivers antimicrobial protection unmatched by any other corrosion resistant coatings.

When a microbe comes in contract with the TurtleCRETE protective coating, the moisture in the organism causes a tiny amount of phosphate to leach from the surface of the ceramic. The pH in the phosphate creates an environment where harmful microbes such as bacteria, fungus, protozoa, or virus, simply cannot survive.

For substrates that must be protected from corrosion that are also in close proximity to humans or animals, such as offshore oil platforms, ships crew quarters, railroad car compartments, livestock feed areas, hospitals, laboratories, hotels, etc...TurtleCRETE offers a safe and superior solution by preventing and eliminating both rust and unwanted bacteria, viruses, fungus, and other microbes.

military infrastructure industry

ULTRA HIGH PERFORMANCE, Extreme Strength, Rapid Set, HEAT & corrosion resistance FOR DEMANDING MILITARY INFRASTRUCTURE...

TurtleCRETE formulas offer military engineers a comprehensive set of concrete construction replacement and repair solutions including extreme compression strength and thermal resistant formulas for VTOL pads, and rapid set formulas for contingency and deliberate operations.

TurtleCRETE formulas set in up to 15 minutes,

and achieve ASTM Compression Strength of 5600psi @ 3 hours, and up to 10500psi @ 28 days

TurtleCRETE is successfully utilized in industrial and military applications for both rapid repair, and new construction.

TurtleCRETE formulas set in up to 15 minutes,

and achieve ASTM Compression Strength of 5600psi @ 3 hours, and up to 10500psi @ 28 days

TurtleCRETE is successfully utilized in industrial and military applications for both rapid repair, and new construction.

extreme abrasion Resistance

TurtleCRETE is a highly abrasion resistant coating that protects critical assets in the toughest environments. From industrial flooring to laboratory countertops, oil storage tanks to gas pipelines, from floating roofs to industrial equipment, TurtleCRETE protects steel, concrete and wood substrates from real-world abrasion.

No traditional Portland cement or epoxy barrier coating can match the true ceramic protection of TurtleCRETE.

More Abrasion Resistant Than Epoxy...

Since TurtleCRETE is a phosphate bonded ceramic coating, it provides an extremely hard surface that is almost impervious to scratches, taking >1200 cycles during abrasion testing, while the number of cycles to get .001” wear for most polymer paints is about 75 cycles, and for an ordinary epoxy it is about 250 cycles.

No traditional Portland cement or epoxy barrier coating can match the true ceramic protection of TurtleCRETE.

More Abrasion Resistant Than Epoxy...

Since TurtleCRETE is a phosphate bonded ceramic coating, it provides an extremely hard surface that is almost impervious to scratches, taking >1200 cycles during abrasion testing, while the number of cycles to get .001” wear for most polymer paints is about 75 cycles, and for an ordinary epoxy it is about 250 cycles.

Chemical Resistant Barrier

TurtleCRETE provides a highly effective barrier to chemicals that would otherwise damage substrates.

After testing protocol was established, the corresponding results for each chemical is as follows:

Chemical Resistance Test Results

Immersion Chemical Resistance Result

Xylene...Excellent

Phenol...Excellent

Methanol...Excellent

IPA (Isopropyl Alcohol)...Excellent

25% Salt Solution...Excellent

37.5% Salt Solution...Excellent

Concentrated Sulfuric Acid...Excellent

Hydrochloric Acid...Excellent

After testing protocol was established, the corresponding results for each chemical is as follows:

Chemical Resistance Test Results

Immersion Chemical Resistance Result

Xylene...Excellent

Phenol...Excellent

Methanol...Excellent

IPA (Isopropyl Alcohol)...Excellent

25% Salt Solution...Excellent

37.5% Salt Solution...Excellent

Concentrated Sulfuric Acid...Excellent

Hydrochloric Acid...Excellent

DoT: Permanent, extreme strength, Quick Set, all weather repair FOR TRANSPORTATION INFRASTRUCTURE

Mandated and specified for use by the Department of Transportation, multiple purpose TurtleCRETE produces superior, permanent structural repair coatings ideal for roads, bridges and any other mass concrete construction application, and meets or exceeds ASTM C1157 & C1600 requirements.

TurtleCRETE is used as an all weather permanent solution for pot holes, and can also be spayed over rusty carbon steel, rebar, concrete and wood to form a chemically bonded, fused protective coating that will not degrade in harsh environments such as extreme temperatures, salt water, brine, or petroleum.

TurtleCRETE's exceptional volume stability, very low chloride permeability, superior freeze thaw durability and inherent resistance to both ASR and sulfate attack represents a quantum breakthrough in concrete repair products, with 5 times the durability of typical Portland cement concretes.

Performance Advantages:

- Enhanced Durability / Low Permeability

-Resists deterioration from de-icing chemicals - ASR Resistant

- Utilize local aggregates - Exceptional Freeze/Thaw Performance

- Superior Volume Stability

-Less cracking potential, fewer control joints required - Less Heat of Hydration

- Set up within 15 minutes, traffic opened within one hour

(depending on application requirement)

By using TurtleCRETE infrastructure can be coated once and then kept in service for decades. Savings can immediately be obtained with faster and less expensive surface preparation and application costs.

In place assets are returned to service faster than if traditional surface preparation and coatings are applied. Year after year no additional funds will be spent on such maintenance.

If organizations and governments care about the increased health and safety of their employees, contractors, and the public as a result of using an inorganic product with no VOCs, no HAPS, no odor, no flash point and zero flame spread, then TurtleCRETE is the solution.

In place assets are returned to service faster than if traditional surface preparation and coatings are applied. Year after year no additional funds will be spent on such maintenance.

If organizations and governments care about the increased health and safety of their employees, contractors, and the public as a result of using an inorganic product with no VOCs, no HAPS, no odor, no flash point and zero flame spread, then TurtleCRETE is the solution.

Industries Served

For those who have millions of dollars in carbon steel, concrete and wood assets,

TurtleCRETE resists extreme temperatures and prevents corrosion where it matters most...

protecting mission critical investments.

Energy

From offshore platforms, to fuel oil pipelines, to oil storage tanks, to natural gas lines...

extreme temperature and corrosion resistant TurtleCRETE can be applied in a thin overlay or built up as needed to protect and insulate carbon steel, concrete and wood assets, increasing profits for energy companies across the globe.

Infrastructure

With pigmentable, DOT specified TurtleCRETE,

infrastructure is coated once... and then kept in service for decades.

Potholes in concrete and asphalt are permanently repaired in all weather conditions...

Bridges and roads are permanently repaired, and traffic opened within one hour...

Dams levees, docks, emergency management containment...all permanently repaired.

This saves money on labor, maintenance, and upkeep.

Marine

Whether protecting marine terminals and dry docks from the ravaging effects of salt water, bird droppings, and UV exposures, or guarding offshore oil & gas platforms against brutal sea water corrosion, U.S. Navy mandated and specified TurtleCRETE delivers unmatched protection for steel, concrete, and wood substrates, as well as non-slip, antimicrobial benefits for everyone on board.

Hazardous and Nuclear Waste Encapsulation

Because TurtleCRETE is a phosphate bonded ceramic, it is the ideal material used as a micro/macro encapsulation for DoE hazardous and nuclear waste streams.

Refractory

Quick setting TurtleCRETE is used as precast applications for refractory crucibles , moulds, and forms, as well as equipment and slab protection.

Refractory crucibles can be precast without using heat to cure, and then utilized in the field the next day.

Sewage Treatment Facilities

TurtleCRETE is used as a protective coating and repair material for waste sewage treatment facilities since it is resistant to UV, sulfuric and hydrochloric acid exposures.

Industrial/Terrazzo Flooring

TurtleCRETE is used as a thin, self leveling, insulative overlay for industrial flooring and resurfacing applications, as well as terrazzo flooring applications. It has the quickest return to service setting up with an hour. Additionally, there's no need to close down public space operations since TurtleCRETE has negligible odors or VOC's.

'Cast-in-Place' Countertops

Quick setting, extreme early strength properties make TurtleCRETE ideal for cast in place countertop solutions, and offers eco and user friendly alternatives to caustic concrete.

TurtleCRETE behaves in much the same way as concrete,

except it won't harm workers or the environment.

It can be decorated, pigmented and finished just like concrete, without all the curing time or hazardous ingredients.

Imagine pouring a countertop, and having it ready to use within an hour!

Fence Post to Wind Farm Anchoring

Everything from fence posts to wind farms benefit using TurtleCRETE as an anchoring material since they are cured in as little as 5 minutes,

as well as having extreme compression strength and corrosion resistance in salt water exposures.

And unlike Portland cement products,

TurtleCRETE will not contaminate environment or water sheds,

and won't destroy plant or fish life.

Lightweight Foamed

TurtleCRETE can be foamed for limitless lightweight precast block, insulative flooring, and

'Earth-ship' and Structurally Insulated Panel Systems(SIPS) applications for truly 'earth friendly' building alternatives..

The Benefits of TurtleCRETE Protective Coatings...

No matter what the industry, TurtleCRETE delivers cost-saving and productivity benefits realized with faster, less expensive surface preparation, and a faster return-to-service.

TurtleCRETE offers permanent metal, concrete and wood corrosion protection, as well as elimination of future surface preparation allowing for additional and significant cost savings to customers.

TurtleCRETE'S inorganic product line improves the health and safety of employees, the public and the environment, and will safeguard your most valuable investments — no matter what your industry.